The final day of mold making on "American Beauty" by the Deep in the Heart crew.

They got here on Wednesday, worked 17 hour days for 4 days, and left Sunday morning having finished a high quality silicon rubber mold of a 4 X life-size sculpture titled "American Beauty."

They loaded up the 81 separate mold sections on their trailer as well as a couple of my large sculptures that Clint will take to his gallery in Austin, Texas.

They left my studio cleaner than when they got here. ( I was very happy about that)

The next step in the "American Beauty" process is casting waxes into the mold sections. This will be done at the Deep in the Heart foundry in Bastrop, Texas (just outside of Austin)

more to come.........

|

| Mold making crew (+ me) |

|

| plaster mother mold cont.... |

|

| building the mother mold flanges |

|

| mother mold pretty much finished |

|

| getting ready to stencil mold IDs on each section |

|

| beginning to stencil |

|

| finished with stenciling |

|

| Clint drilling alignment holes in mother mold |

|

| first mold section being removed |

|

| off comes the mother mold section |

|

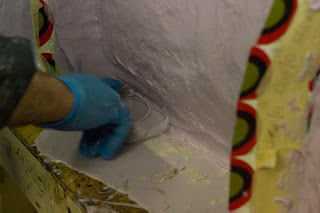

| cleaning up the rubber mold sections |

|

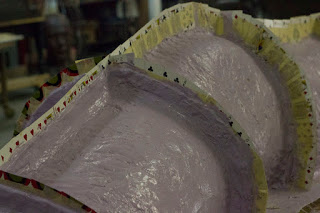

| removed mold sections layed out |

|

| 50 mold sections on the torso alone |

|

| matching rubber to mother molds |

|

| mold almost completely removed |

|

| Patty helped match rubber to mother mold sections |

|

| mold removal done, loading the trailer |

|

| Early Saturday evening |

|

| beginning to load mold |

|

| Gary strapping down "Paradise" |

|

| Beginning studio clean up |

|

| rolling up tarp |

|

| moving torso off the tarp |

|

| Tarp is rolled up with all the debris |

|

| Tarp went directly to the dumpster |

|

| early Sunday morning; ready to roll back to Austin |

|

| So long!! |