Day two of rubber mold making with the Deep in the Heart Art Foundry crew.

The first unthickened coat of rubber is almost completely finished. The silicon rubber is white but the normal set catalyst is purple which gives the first coat the lilac tint. The second coat is slightly thickened and some higher speed catalyst is used which changes the color to tan and makes it easy to see where the new rubber has been applied. The third coat is very thick and applied like putty.

Today is the third day of the crew being here. I expect the rubber to get finished today......next up, plaster mother mold.

|

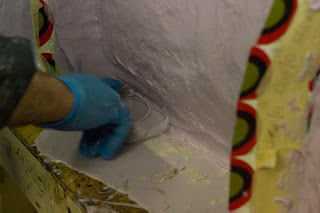

| last of the first coat going on |

|

| Gary is blowing the fresh rubber with compressed air to pop any trapped air bubbles |

|

| second coat going on |

|

| Clint pouring rubber into the belly button |

|

| beginning to add the thickened third coat |

|

| spreading it out |

|

| third coat is applied to the entire surface first, only then applied to the shim line |

|

| mixing more rubber |

|

| preparing the second drum of rubber for use |

|

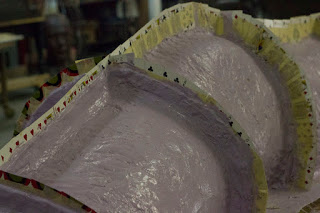

| at the end of day 2, leg rubber is done, torso almost done |

|

| Keys have been added and rubber flanges trimmed |